The fabrication industry is a wide field where different activities take place. In most cases, most products are always in three phases, including the prototype, production, and mass production. However, during the manufacturing process, the three phases have some distinctions, as explained in the article. Also, you can Visit website to explore more ideas on the same and explore the products.

Differentiating prototypes, production, and mass production

Prototype phase

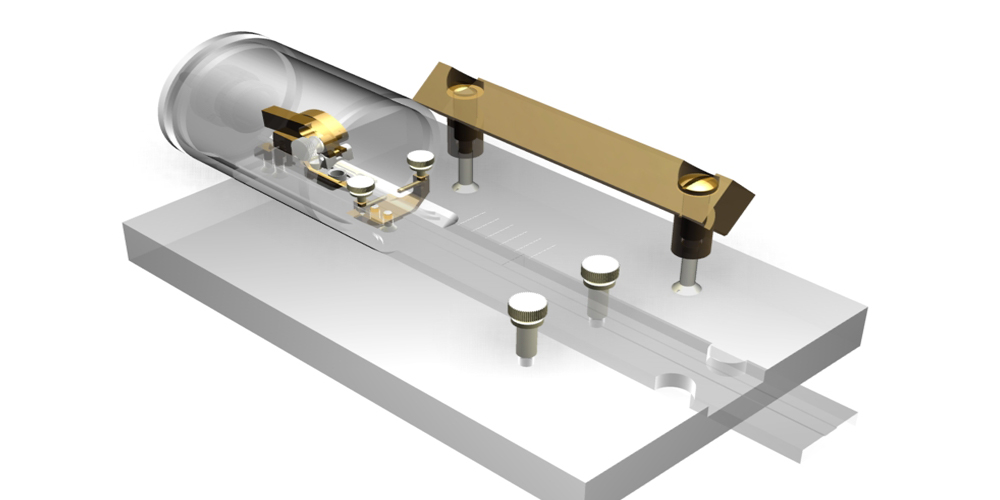

Also known as product or part development, it is the initial or first stage of your product development. Since this is a technical stage and the basis of your product, you will need to work with experts, i.e., engineers who know what it takes to develop an incredible product. This move is to help you save time and money to avoid making changes at a later stage, which can be costly. The aim of the prototype stage is to establish a perfect design through testing and changing where possible. Once you settle on the best design, then you can move to the next stage of production.

The quantity produced at this phase usually varies depending on the product and the company—however, the ideal range is from 1 to 100. One aspect you should note about the prototype phase is that it is quite expensive to fabricate since the costs for setting up are within low quantities, and there are fewer economies of scale.

When fabricating prototypes, you can use different hardware and materials, then finish with what you ought to use in the production stage to authenticate the design- this is known as rapid prototyping.

Note that some prototypes require the exact material and hardware of the part before the production stage. So, the manufacturers should always have a say during the process to ensure the process is smooth.

Production Stage

Also known as batch production, this is the second stage in product development whereby part of the product is introduced, and the growth starts taking place. This stage is also known as batch production because parts of the products are produced in the 50s, hundreds, or thousands of batches. In the company’s setting, the different departments are specialized in different activities. For instance, one department will perform fabrication as the product move to the next department. Here, the costs are much lesser compared to the prototype stage since most of the work is done, and the batch production which eases and simplifies the process.

Mass production stage

Finally, this is the last stage, and it is also called repetitive flow production. Here, your part or product has finally reached the highest level after approval from the prototype stage and the production stage. Your product can only reach the mass production stage after the overall production has reached a stage where there is consistency in demand and the products have reached thousands.

Conclusion

The product production has different phases that must take place before the final stage. Each stage is equally important because it determines what will happen in the next stages. If you didn’t understand prototypes, production, and mass production, I hope this article has shed some light.